Sections

Overview

Picking is the step in the Outbound Order process where you select Materials to Ship for an Order, and assign them to a new Location in preparation for the Shipment. Cluster Picking allows you to group Pick Slips or Shipments together to minimize the amount of work required for Picking, collecting all like Materials or Picking all Materials from the same Location at once.

From here you can...

Pick Slip Clusters

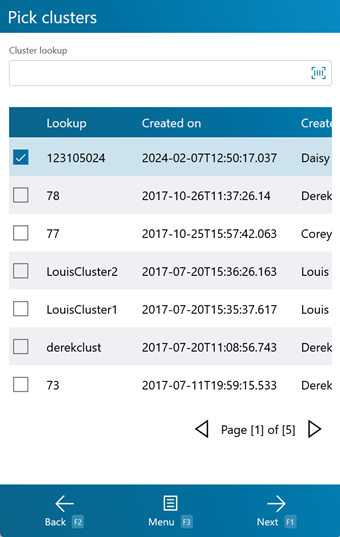

This screen lists all created Pick Slip Clusters for the mobile device.

The Cluster Lookup field allows you to filter the displayed Pick Slip Clusters by LookUp Code or UPC.

Tapping Next: F1 or pressing the F1 key takes you to the Build Pick Slip Cluster screen for the selected Pick Slip.

Tapping Menu: F3 or pressing the F3 key displays a menu with three additional options:

- New Pick Slip Cluster: F4 brings you to the Build Cluster for Pick Slips screen in order to create a new Cluster.

- Refresh: F5 refreshes the information displayed on the screen, filtered by any entered LookUp Code.

- New Container Cluster: F6 brings you to the Build Cluster for Container screen in order to create a new Container Cluster.

- Inquiry: F11 opens the Inquiry Menu.

Tapping Back: F2 or pressing the F2 key takes you back to the main menu.

| LookUp: | The Pick Slip Cluster LookUp Code. |

| Created On: | The date on which the Cluster was created. |

| Created By: | The Footprint User who created the Cluster. |

| Cluster Type: | The Type of Cluster (Pick Slip or Container). |

Build Pick Slip Cluster

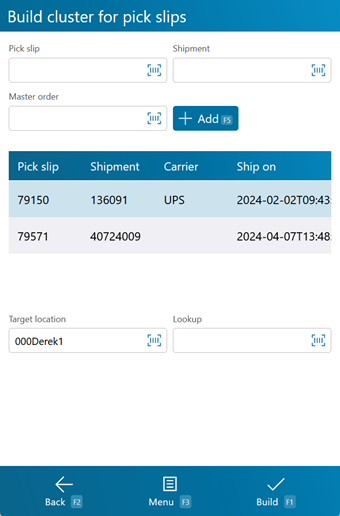

This screen allows you to create a Pick Slip Cluster by adding Pick Slips or Shipments to the Cluster, then confirming. If the Cluster has already been created, this screen displays all Pick Slips that are part of the Cluster. You can still add Pick Slips to a created Cluster.

Scan or enter the Pick Slip number, Shipment number, or Master Order number in the appropriate field, and tap the blue + Add F5 button or press the F5 key to add all Pick Slips associated with the entered information to the list. If any relevant Pick Slips are already attached to another Pick Cluster, they will not be added.

The Target Location field displays the name of the Mobile Device you are using, which the Pick Cluster will be tied to.

Note

You must complete the Cluster Pick on this Mobile Device once it is created.

Tapping Build: F1 or pressing the F1 key, confirms the listed Pick Slips and takes you to the Pick Tasks screen for execution of the Cluster.

Tapping Menu: F3 or pressing the F3 key displays a menu with three additional options:

- Remove Pick Slip: F4 removes the selected Pick Slip from the Cluster.

- Search: F5 refreshes the information displayed on the screen, filtered by the entered parameters.

- Inquiry: F11 opens the Inquiry Menu.

Tapping Back: F2 or pressing the F2 key discards the selected Pick Slips, and takes you back to the Pick Slip Cluster screen.

| Pick Slip: | The LookUp Code of the added Pick Slip. |

| Shipment: | The ID number of the added Shipment. |

| Carrier: | The Carrier making the delivery. |

| Ship On: | The date on which the Shipment is scheduled. |

Pick Tasks

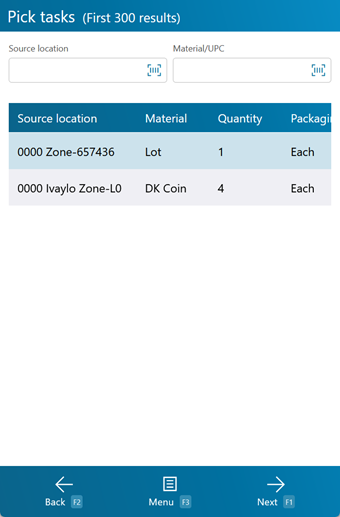

The Pick Tasks screen allows you to select which Pick Tasks from the Pick Slip you'd like to perform.

Scanning or entering a Source Location or Material/UPC filters the displayed Tasks by that Location or Material.

Tapping Next: F1 or pressing the F1 key allows you to Pick the selected Task on the Cluster Pick screen.

Tapping Menu: F3 or pressing the F3 key displays a menu with these additional options:

- Inquiry: F11 opens the Inquiry Menu.

Tapping Back: F2 or pressing the F2 key takes you back to the Build Pick Slip Cluster screen.

| Source Location: | The Location of the Materials to be Picked. |

| Material: | The LookUp Code of the Material. |

| Quantity: | The number of Packages of the Material to be Picked. |

| Packaging: | The packaging Type of the Material to be Picked. |

| Lot: | The Material's Lot. |

Cluster Pick

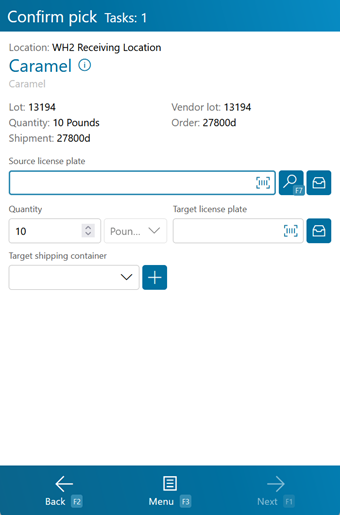

The Cluster Pick screen is where you confirm the Materials you are Picking, where they are coming from, and where they are going.

Basic information about what and where you are Picking is displayed at the top of the screen.

In the center of the screen is where you enter or scan all Pick information.

Tapping Next: F1 or pressing the F1 key confirms the Pick for all selected Pick Slips.

Tapping Menu: F3 or pressing the F3 key displays a menu with three additional options:

- Pick Drop: F4 opens the Pick Drop screen.

- Select Source LP: F7 allows you to select a Source LP for your pick from a list of potential License Plates (each containing the relevant Material).

- Reallocate: F8 opens the Reallocation screen.

- Report Missing LP: F9 opens the Missing License Plate screen.

- Create a Task Notification: F12 allows you to crate a Task Notification and enter a message.

- Source Container Type allows you to define the Container Type for the Source License Plate.

- Target Container Type allows you to define the Container Type for the Target License Plate

- Cancel Task lets you Cancel the Pick Task.

- Next Task opens the next Pick Task in the Pick Cluster for completion, without completing the current Task.

- Previous Task opens the previous Pick Task in the Pick Cluster for completion, without completing the current Task.

- Capture Temperature allows you to take a Temperature Capture reading.

- View Material Details displays the Material Inquiry results screen for the current Material.

Tapping Back: F2 or pressing the F2 key takes you back to the Pick Tasks screen.

*Those in red are required fields.

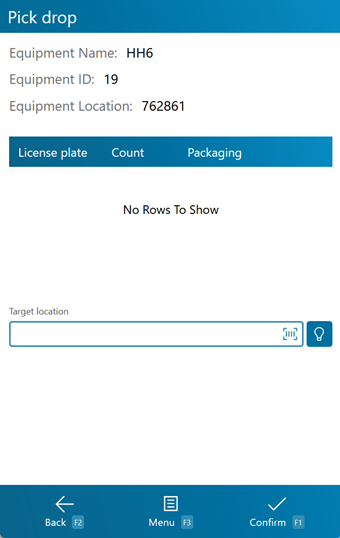

Pressing the F4 key allows you to perform a Pick Drop, which unloads License Plates assigned to the Mobile Device to a specified Location.

Scan or enter the Location at which you are dropping off the License Plate in the Target Location field.

Tapping Next: F1 or pressing the F1 key confirms the Pick Drop for the selected License Plate.

Tapping Menu: F3 or pressing the F3 key displays a menu with these additional options:

- Recommended Location: F4 will populate the Target Location with a Recommended Location.

- Inquiry: F11 opens the Inquiry Menu.

Tapping Back: F2 or pressing the F2 key takes you back to the previous screen.

| License Plate: | The License Plate LookUp Code. |

| Count: | The number of unique Materials on the License Plate. |

| Packaging: | The Packaging Type for the Materials on the License Plate. |

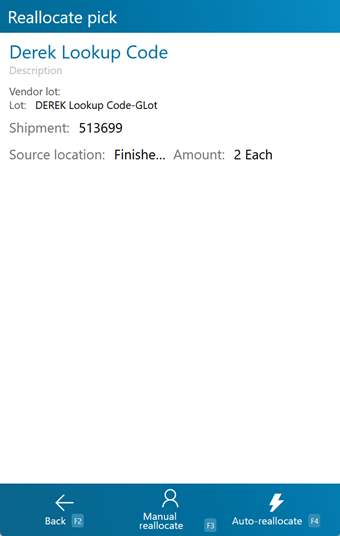

Pressing the F8 key allows you to Reallocate the Materials, using a different Source Location for the Materials.

Tapping Manual Reallocate: F3 or pressing the F3 key allows you to choose the Source Location for the Materials.

Tapping Auto-Reallocate: F4 or pressing the F4 key has the system choose a new Source Location for the Materials.

Tapping Back: F2 or pressing the F2 key takes you back to the previous screen.

| Material: | The Material to be Reallocated. |

| Vendor Lot: | The Vendor Lot for the Materials to be Reallocated. |

| Lot: | The Lot for the Materials to be Reallocated. |

| Shipment: | The Shipment for the Materials to be Reallocated, if applicable. |

| Source Location: | The current Source Location from which the Materials have been Allocated. |

| Amount: | The number of Packages of the Material to be Reallocated. |

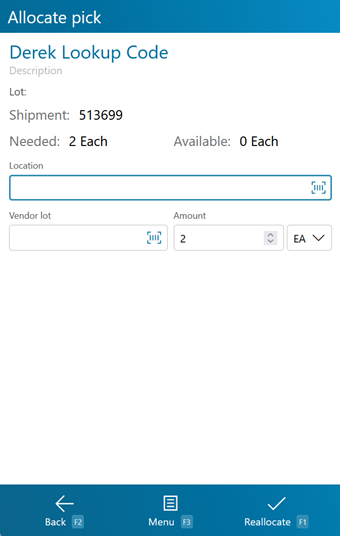

Tapping Next: F1or pressing the F1 key completes the Reallocation, changing the Source Location.

Tapping Menu: F3 or pressing the F3 key displays a menu with these additional options:

- Inquiry: F11 opens the Inquiry Menu.

Tapping Back: F2 or pressing the F2 key takes you back to the previous screen.

| Material: | The Material to be Reallocated. |

| Lot: | The Lot for the Materials to be Reallocated. |

| Shipment | The Shipment for which you are Allocating. |

| Needed: | The expected number of Materials for the Shipment. |

| Available: | The number of Materials in the Location available to be Allocated. |

| Location: | Enter the new Source Location from which the Materials will be Allocated. |

| Vendor Lot: | The Vendor Lot for the Materials to be Reallocated. |

| Amount: | The number of Packages of the Material to Reallocate. The Packaging Type is displayed next to the field. |

| UOM: | The Material's Unit of Measure. |

*Those in red are required fields.

The Report Missing License Plate screen allows you to enter a License Plate LookUp Code for the missing License Plate, and select a Reason Code for why it's missing. Both fields are required.

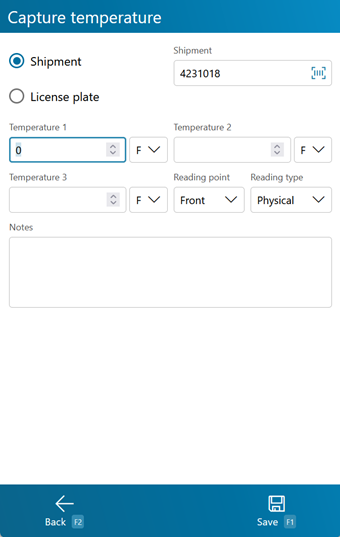

Opening the Capture Temperature screen allows you to record temperature readings for the operation, and tie them to the Shipment or License Plate.

Selecting Shipment or LP determines whether the Temperature Capture information will be associated with the Shipment or the License Plate in question. The field below this choice will be automatically populate from the previous screen, but can be overwritten to assign the capture to whichever Shipment or License Plate you'd like.

You can enter up to three Temperature Readings, and select whether the temperature was recorded in Fahrenheit or Celsius.

The Reading Point and Reading Type can also be chosen for the reading, further specifying information by selecting from various customizable options configured on the Desktop.

Additional Notes can be recorded for the reading.

Tapping Save: F1 or pressing the F1 key saves the temperatures entered for the chosen Shipment or License Plate. Additional Temperature Readings can be recorded.

Tapping Back: F2 or pressing the F2 key closes the Temperature Capture screen, returning you to the previous screen. Any unsaved changes are discarded.

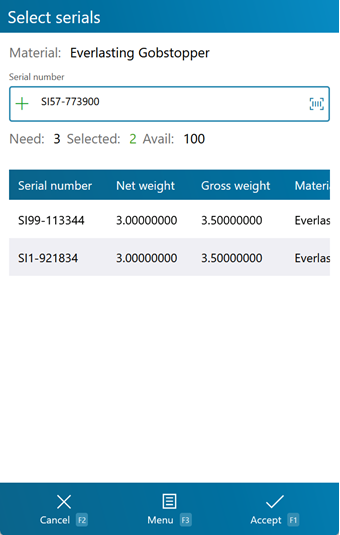

Serial Number Pick

If the Materials you are Picking are Serialized, or have Variable Weight or Dimensions, you will be brought the Serial Information screen once you Confirm Picking.

At the top of the screen, under the Material, is the Serial Number field in which you scan or enter the Serial Number you have selected.

Displayed under this field are the amount of Serial Numbers that Need to be Picked, the amount of Serial Numbers already Selected, and the total Available amount of Serial Numbers available to choose from.

The list pane on the lower half of the screen shows all selected Serial Numbers.

Tapping Accept: F1 or pressing the F1 key confirms all Serial Numbers selected.

Tapping Menu: F3 or pressing the F3 key displays a menu with these additional options:

- Select Unwanted Serials: F4 switches the goal of the screen to scanning the Serial Numbers you are not choosing, rather than those you are. This is good for situations where you will be selecting more than half of the Serial Numbers that are available here.

- Refresh: F5 populates the top window with most current information for the scanned Serial Number(s).

- Auto Select: F8 automatically selects the Needed amount of available serials.

- Deselect All: F9 Deselects all selected Serial Numbers, clearing the list.

- Inquiry: F11 opens the Inquiry Menu.

Tapping Cancel: F2 or pressing the F2 key takes you back to the previous screen.

| Serial Number: | A unique Serial Number to identify the item. |

| Net Weight: | The Net Weight of the item, without its Packaging. This box should be filled out for variable weight Materials. |

| Gross Weight: | The Gross Weight of the item, including their Packaging. This box should be filled out for variable weight Materials. |

| Material: | The Name of the Material. |

| Lot: | The Lot of the Material. |

| Packaging: | The Packaging for the Material. |

| Last Updated: |

| 06/06/2025 |